Automation

Installation

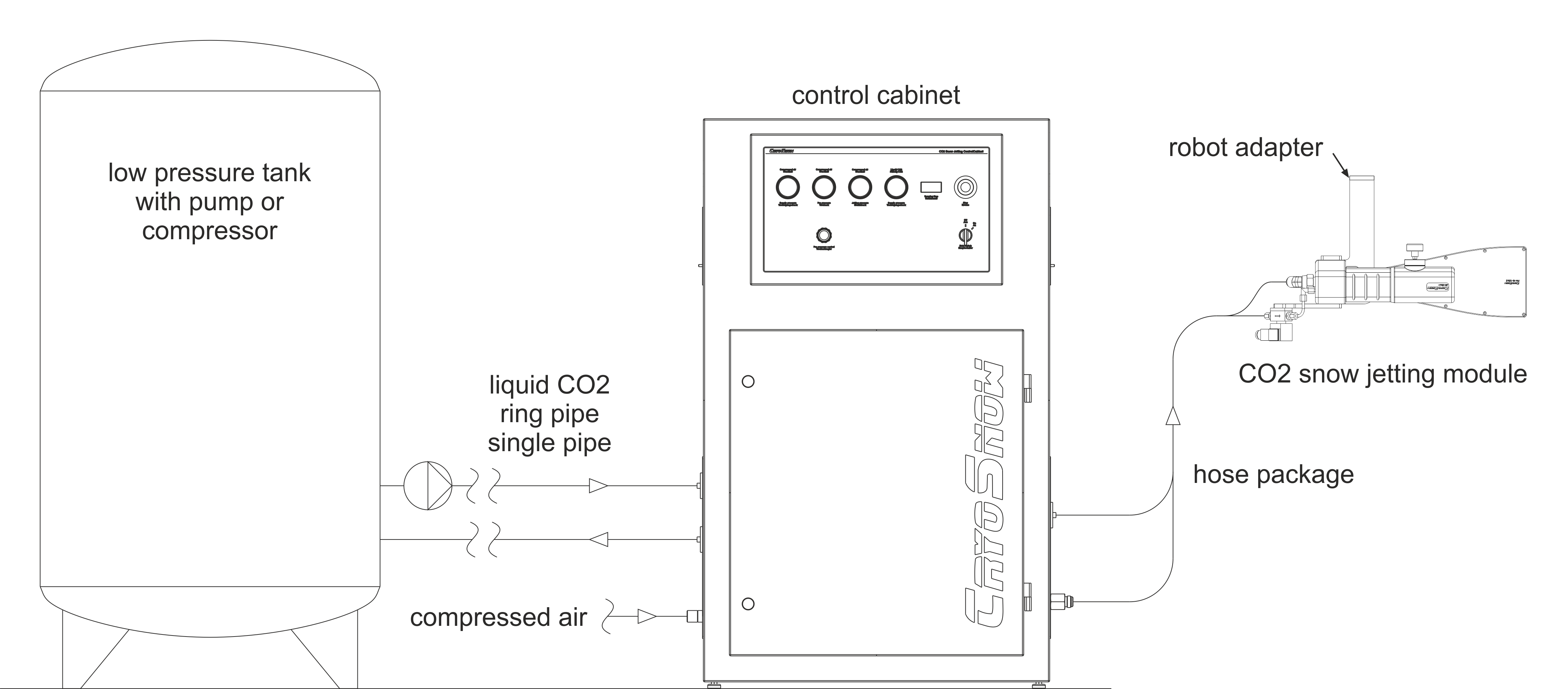

Automated CO2 snow blasting equipment has been realized in continuous operation (24 hours per day, 365 days per year). By using a control cabinet, it is possible to control and monitor one or more CO2 snow blasting nozzles. The equipment is designed and manufactured according to customer requirements.

The liquid CO2 is supplied using a low pressure tank, a booster pump and an insulated CO2 ring circuit. The compressed air supply is provided either via the house network or via a screw-type compressor. The ControlCabinet includes state-of-the-art technology for the necessary safety components, operating controls, process controls and monitoring processes. The CO2 snow blasting nozzle is fitted with a robotic adapter and when this interface is used, it is possible to either fix the machine securely or more flexibly, adapt it to a portal or axle robot. The liquid CO2 has a temperature of approx. -20 °C when a low pressure tank is used. Therefore all pipe lines and hoses are thermally insulated. The booster pump and the insulation guarantee that the CO2 is always liquid even with long supply lines. The tank content is monitored completely automatically and when necessary will be filled from a gas supplier’s fuelling vehicle. This supply concept keeps operating costs low.

If the amount of CO2 used is minimal then the supply generally can be completed using either CO2 cylinders or bundles with a dip tube. Only in this case can an automation be realized with manual standard equipment and an AutoControl unit.