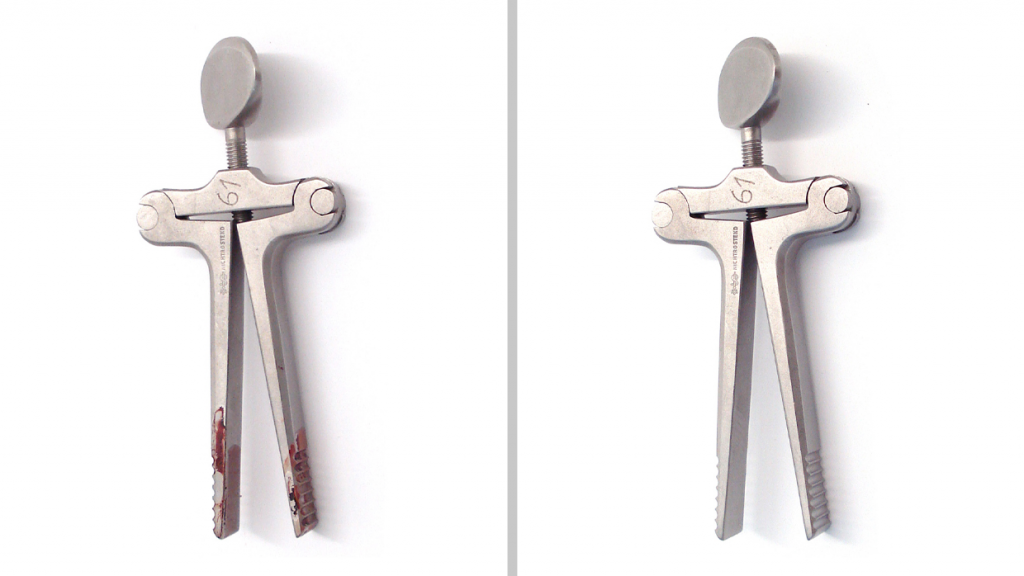

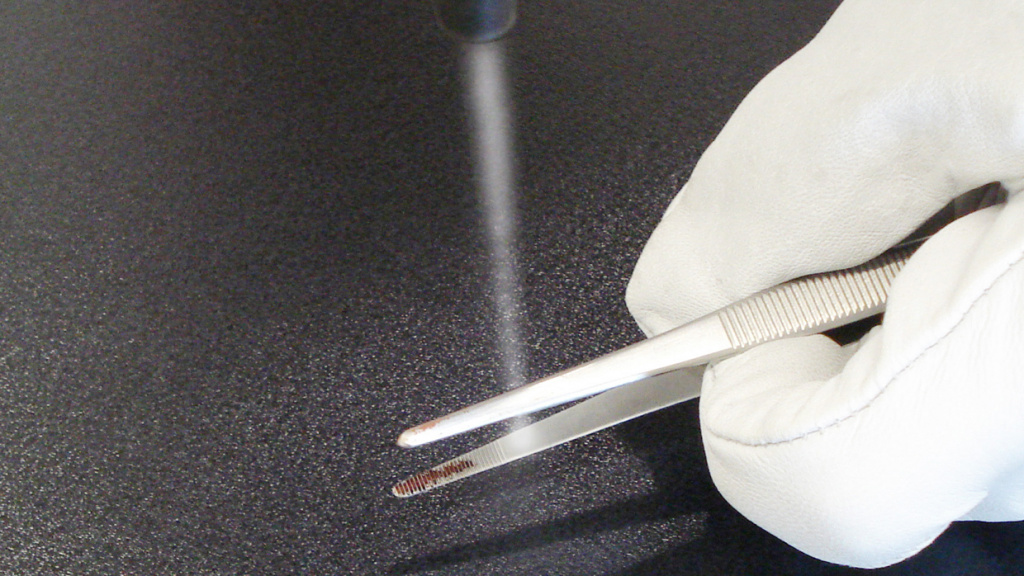

Cleaning of medical, glass, ceramic, semiconductor components

- Meets the highest purity requirements

- No functional impairment of electronic components

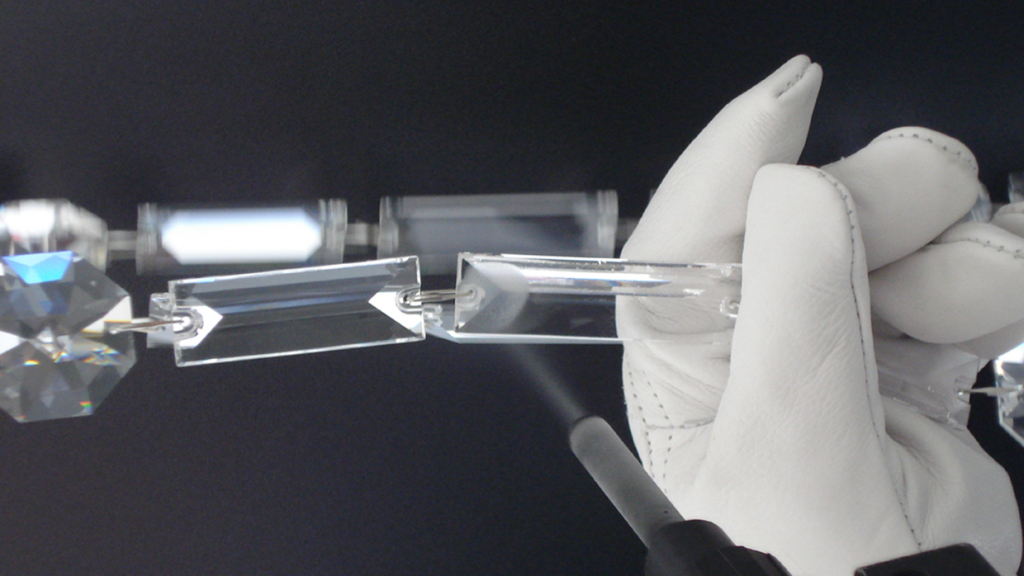

- Surface-gentle

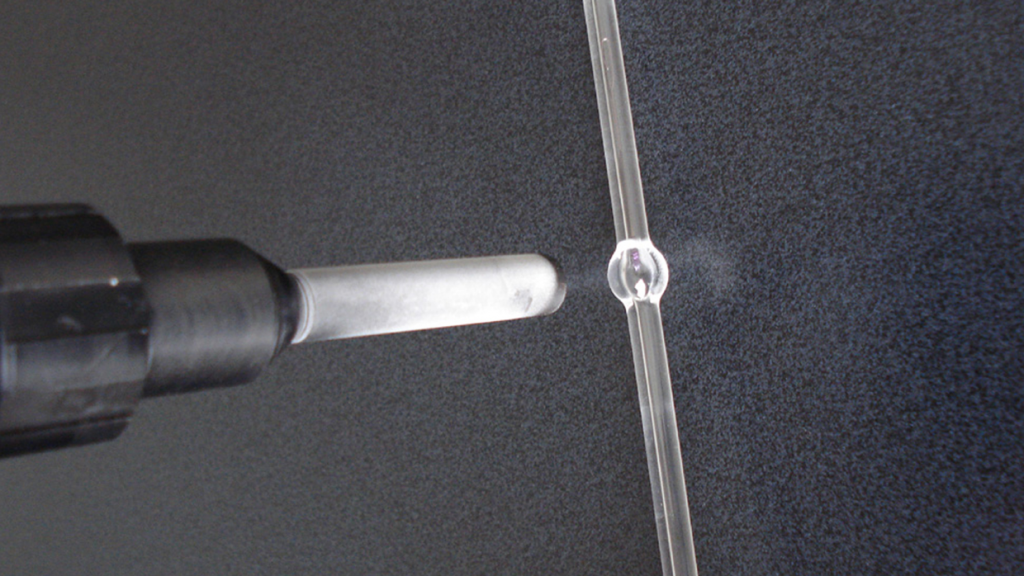

- Cleans even the finest cavities

- Special sound-insulated blasting cabin for manual work available

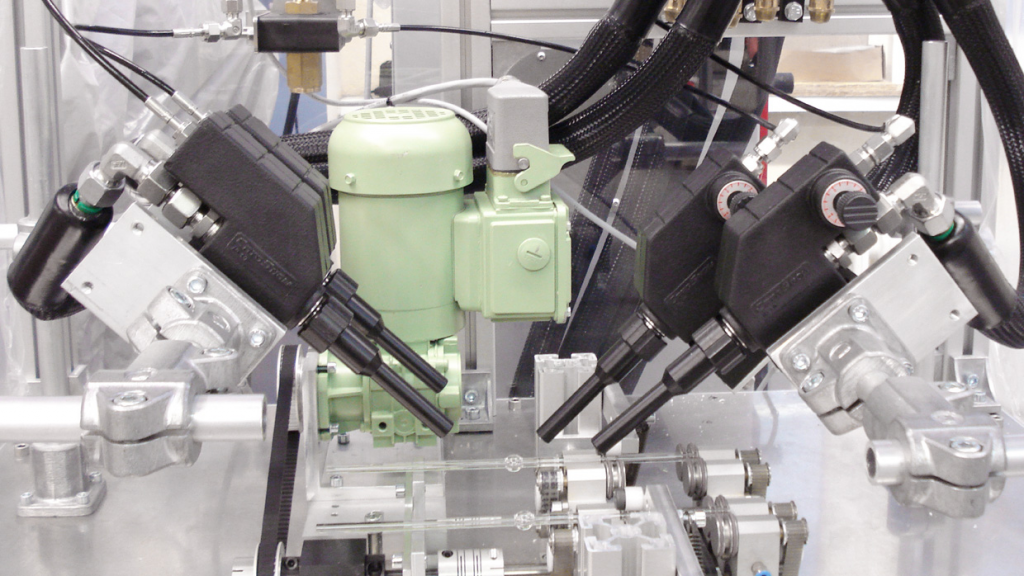

- Nozzle movement with robot or linear axis

- Little required space

Medical, semiconductor and glass components or assemblies can be pretreated prior to further processing using the CryoSnow process.

The following impurities/deposits are removed from the substrate:

- Traces of smoke

- Oil and fat

- Production residues, such as release agents

- Fingerprints

- Dust and fiber