Examples of application

Various uses.

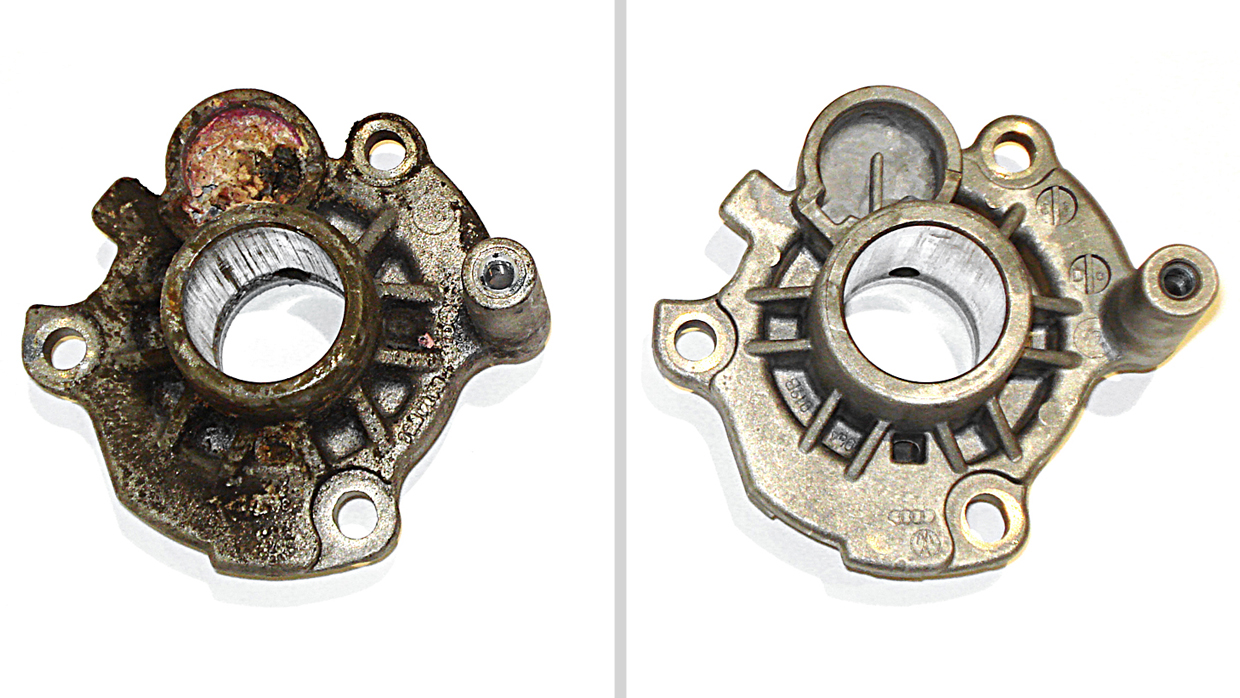

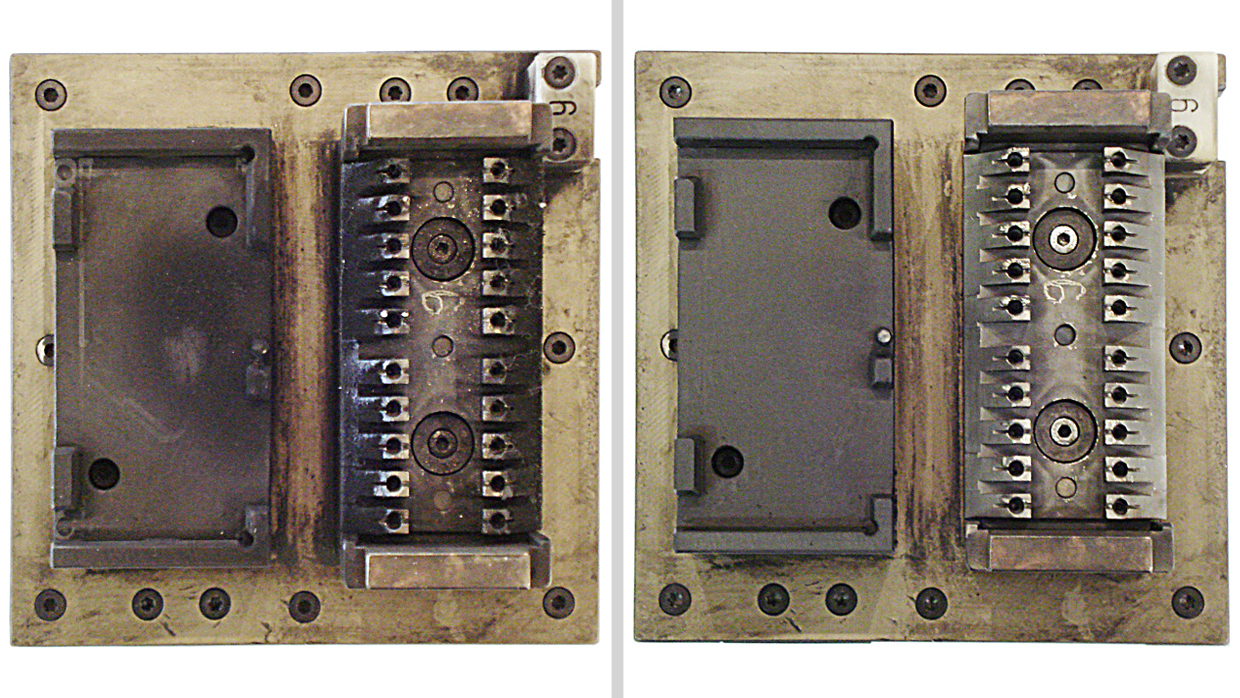

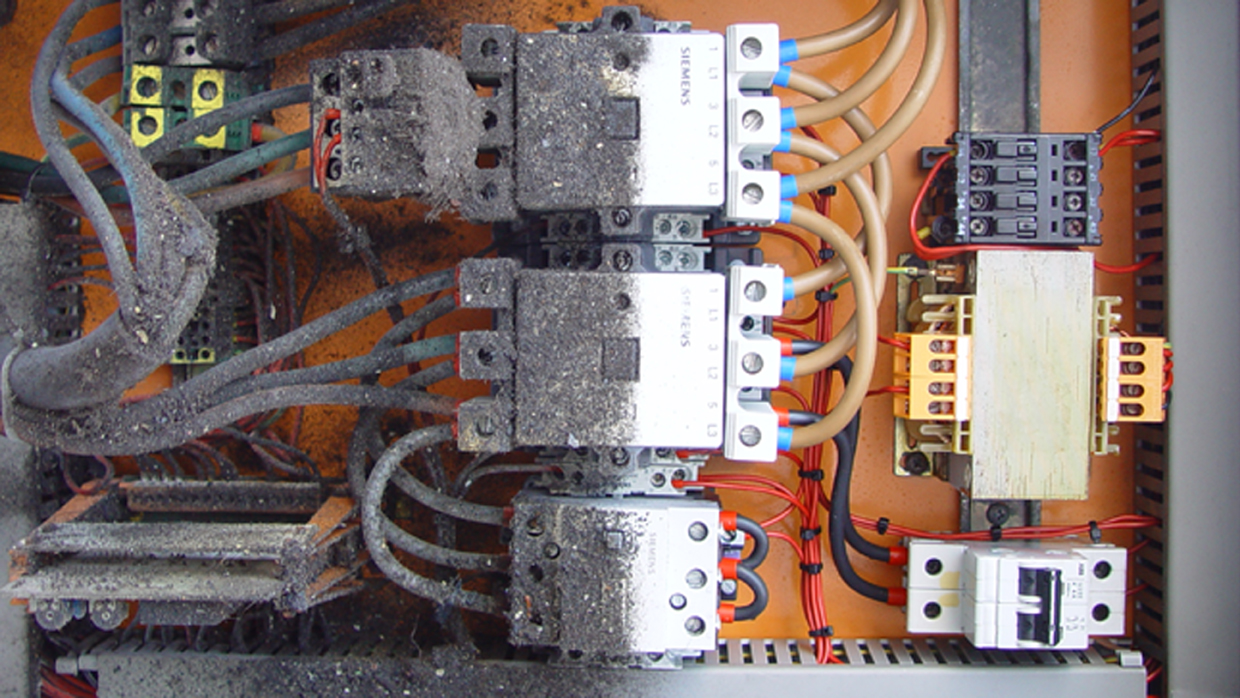

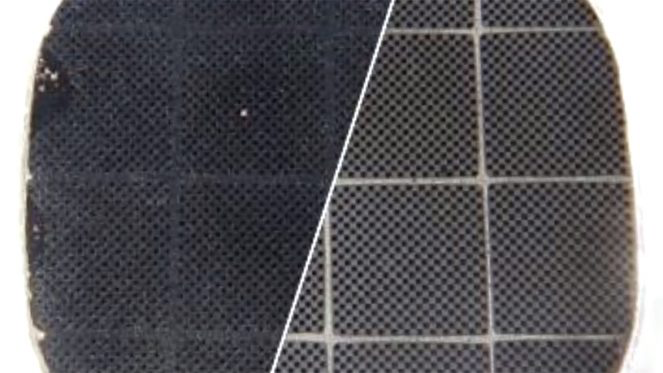

CO2 snow blasting offers a great deal of application flexibility and is used for the following contaminants: particles, dusts, fats, oils, fingerprints, release agents, sizing, product residues, adhesive and glue deposits, polishing agent residues, anti-corrosive and cooling lubricants, bitumen, waxes, paint particles and thin layers of paint , traces of smoke, flux deposits, soot, lime and germs and fungi.